Seam welding is an essential process in the manufacturing and metalworking industries. It uses spinning wheel-like tools to make a series of welds that overlap, creating a strong and tightly sealed connection. This blog aims to explain seam welding, its types, equipment, and applications.

Seam welding is a resistance welding process where rotating wheel electrodes replace the typical spot welding electrodes. These wheels make a row of connected welds, one after another, without any gaps. This makes a seam that is similar to spot welding but better because it creates a strong, leak-proof joint

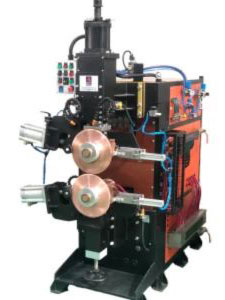

The process involves two rotating wheel electrodes that apply pressure and electrical current to the material being welded. The electrodes roll over the workpiece, creating a series of spot welds that overlap, forming a continuous seam. The key difference between seam welding and spot welding is the use of rotating wheels instead of fixed electrodes.

Seam welds can be categorised into two main types: seam welds and roll spot welds.

Seam welds are continuous and leak proof. They require higher continuous currents than spot welds and are used when a strong, leak-proof joint is necessary.

Roll spot welds are like seam welds, but the timing is different. They don’t seal out gas or liquid. In roll spot welding, you make spot welds with breaks in between to keep them from overlapping.

Seam welding machines come in two general types: longitudinal and circumferential.

Longitudinal Seam Welding machines feed the component into or out of the machine’s throat. These machines are used for straight seam welding operations.

Circumferential Seam Welding feeds the component across the machine’s throat, suitable for Circumferential Seam welding or curved seam welding.

Universal Seam welding machines can be configured for either longitudinal or Circumferential Seam welding seam welding, providing flexibility in welding operations.

The wheels can either move the metal through the machine or spin by themselves when the metal is pulled through.. There are two main drive types:

Lap seam welds involve placing metal sheets on top of each other and welding them together. Here are different types:

Butt seam welds join two pieces of metal edge-to-edge using roller electrodes.

Seam welding is great for making fast, strong, and good-looking welds. It’s used in many industries, such as making cars, aeroplanes, and containers. This process can weld thin to thick pieces of mild steel, from 0.5 mm to 2 mm thick, at speeds from a 1.2 meter per minute to over 4 meters per minute.

The aerospace industry, renowned for its high standards, uses seam welding for the construction of vital components such as fuel tanks and pressure vessels. Seam welding machines create continuous welds, ensuring the strength of aeroplanes and other amazing structures.

In automotive manufacturing, seam welding is used for leak proof welding of fuel tanks. This welding plays an important role in ensuring the safety of vehicle.

Conclusion

Seam welding is a versatile and efficient process that creates strong, continuous welds. By learning about the different types of seam welds, the tools used, and how to do it right, you can make strong, high-quality welds. Whether you’re making cars, aeroplanes, or other products, seam welding is a dependable way to join metal pieces together.

Arm Welders Pvt. Ltd. is an India-based global resistance and spot welding manufacturing company. With a keen eye for technical innovation, the company is also a frontrunner for Robotic Automation in a plethora of sectors. Arm Welders product range has been approved for use by large automotive OEMs in both domestic and international markets. With a historic legacy of 45+ years and a futuristic vision, Arm Welders continues to grow its global footprint with exceptional technology and quality manufacturing.